Heritage Builder.

Dale McCabe

Promoting the use of natural materials suitable for modern living.

About

In with the Old, Out with the New.

At Breathe Heritage, we care for and revive the fabric of historic UK homes using traditional techniques. Built from earth, lime, stone, and timber, these natural materials have shaped Britain’s domestic architecture for millennia, and should continue to do so. This timeless approach is not only a sustainable building method but, with materials sourced locally, every home is harmoniously balanced with the nature around it. By using these breathable, flexible materials, we ensure homes as old as the hills thrive, offering safe, comfortable sanctuaries for generations to come. Based in Cambridgeshire, we blend the expert use of modern tools with traditional methods and craftsmanship, preserving heritage more efficiently than previously possible. We keep history alive — one home at a time. Discover how we can breathe new life into your historic property.

What is it?

Cob

Building on our foundation in heritage preservation, we are masters of cob. Bringing a lifetime of experience passed down through generations—from Kevin McCabe to Dale McCabe at Breathe Heritage—we specialize in this ancient natural building material. Cob is composed of clay subsoil, sand, straw, and water. This environmentally friendly mixture offers you excellent thermal insulation for both hot summers and cold winters, as well as unsurpassed breathability to prevent any damp mould building up—and, coming from the ground, it can be almost free, making it a cost-effective choice for sustainable vernacular architecture. In Devon and southwest England, where ideal subsoil is abundant, cob enables traditional hand-built (and foot-stomped) monolithic structures, layered course by course—perfect cosy homes (or castles, like Kevin's Grand Designs project) of cob construction.We also craft cob blocks and make earth-based mortars, which are ideal for historic building repairs and restorations needing earth building materials in the UK. Elsewhere in the country, similar earth-based building methods include Clay Lump, Mud & Stud, and Wattle & Daub—all leveraging similar ingredients but adapted to varying molecular structures of the available subsoils and regional techniques. Forget studwork and gypsum-covered partition walls; imagine solid walls that don't transfer noise like studwork does, they regulate humidity naturally, preventing damp issues (common in older properties which have had cement render applied), while delivering immense durability and a natural aesthetic with a totally unique and charming character. As well as straight partition walls, these techniques lend themselves to creating curved, organic shapes that otherwise can be more complicated to achieve. Further cementing their place in natures naturally ocurring stuff

What is it?

Lime

Lime, derived from calcining limestone (calcium carbonate) and combining it with water (creating calcium hydroxide), is a versatile natural building material used as mortar, plaster, or render for porous brick, stone, earth, and timber structures in historic UK homes—from base coat mortars to natural finishing paints (such as limewash), and even limecrete floors or fireproofing inside thatched roofs. Its hygroscopic nature allows walls to breathe and vapour to pass through while evaporating excess moisture from the air to prevent dampness, all while self-regulating a healthy level of background humidity—creating more comfortable and naturally breathable living spaces.Environmentally friendly and flexible, lime accommodates structural movement without cracking, ensuring longevity and imparts an endearing, soft aesthetic to both traditional and modern architecture. We champion the use of mature lime putty, which is the most flexible and breathable form of lime. This is then combined with a variety of sands, aggregates and fibres depending on what's appropriate for each given application. Where more durable results are required, for example the flaunching of a chimney, we can substitute the mature lime putty with hydraulic lime, which sets primarily through a chemical reaction with water (hydration) as well as carbonation, rather than primarily through carbonation alone. This allows it to be used in damper, harsher conditions, at the expense of some breathability and flexibility. It is important to know the limitations of lime and which mortars are appropriate to use in which scenario.At Breathe Heritage, we specialize in all lime mortar UK applications, drawing on extensive expertise in sustainable lime plaster and breathable lime render. We craft our own mortars onsite using traditional methods—including earth (cob) lime mortar mixes for earth buildings—while recycling and salvaging old materials wherever possible to minimize waste, maximise sustainability and preserve heritage authenticity. This approach is ideal for vernacular architecture across the UK, from repairing ancient stone cottages in the Cotswolds to restoring timber-framed buildings in East Anglia.

Environmentally friendly and flexible, lime accommodates structural movement without cracking, ensuring longevity and imparts an endearing, soft aesthetic to both traditional and modern architecture. We champion the use of mature lime putty, which is the most flexible and breathable form of lime. This is then combined with a variety of sands, aggregates and fibres depending on what's appropriate for each given application. Where more durable results are required, for example the flaunching of a chimney, we can substitute the mature lime putty with hydraulic lime, which sets through chemical reaction rather than through carbonation. This allows it to be used in damper, harsher conditions, at the expense of some breathability and flexibility. It is important to know the limitations of lime and which mortars are appropriate to use in which scenario.At Breathe Heritage, we specialize in all lime mortar UK applications, drawing on extensive expertise in sustainable lime plaster and breathable lime render. We craft our own mortars onsite using traditional methods—including earth (cob) lime mortar mixes for earth buildings—while recycling and salvaging old materials wherever possible to minimize waste, maximise sustainability and preserve heritage authenticity. This approach is ideal for vernacular architecture across the UK, from repairing ancient stone cottages in the Cotswolds to restoring timber-framed buildings in East Anglia.

What is it?

Stone & Timber

Stone can be incredibly eco-friendly when sourced locally. It is a very durable and beautiful building material used for walls, foundations, and façades in historic and modern UK structures. In different parts of the UK you can find many different types of stone in different shapes, sizes and colours. For example in East Anglia you can find church's that dominate their surroundings with a black façade of flint, in the Cotswolds you find beautiful, honey-hewed stone houses, and in Cornwall there are weather-beaten blue slate stone rooves and walls that will outlast us all. Its exceptional strength and thermal mass regulate indoor temperatures, while the rugged elegance of a well-pointed stone wall creates irresistible and sustainable architecture both internally and externally.Timber, sourced from sustainably managed forests, is a versatile material for framing, roofing, cladding, and finishes in traditional and contemporary homes. Its natural strength and workability, combined with distinctive beauty, make it ideal for eco-friendly designs. Naturally breathable and flexible, timber promotes indoor comfort and, with proper treatment, offers resilient protection, bringing traditional materials into modern life.

The Coach House – 18th-century, East Anglia (Conservation Area).Tucked away in a quiet East Anglian village conservation area, this 18th-century coach house required the careful, sympathetic approach that all heritage buildings deserve. Although the gable looked sound from a distance, close inspection revealed around 150 severely spalled bricks and extensive areas of mismatching, impermeable cement mortar that were trapping moisture and generally having a detrimental impact on the building. We carefully replaced the damaged bricks with matching reclaimed bricks provided by the customer, removed all cement repairs and rebuilt affected sections using breathable lime putty mortar. The entire gable was then deeply repointed – in many places up to 100mm – well beyond the usual 20-25mm depth and finished with brushed, recessed joins. During the work we uncovered a few large, fortunately unoccupied masonry bee nests; once sealed behind fresh lime mortar the bees will simply find new homes to nibble at when they emerge this spring. The wall is now stable, fully breathable and protected for future generations while retaining the maximum amount of original fabric and cementing it's natural place on show in this conservation area.

Gable end, before

Gable, after

North elevation, before

North elevation, after.

ELLON HOUSE - An 18th-century house, partially embedded in a hillside, suffered from severe damp issues. The elevation was fully underpinned during excavation, with repairs carried out to walls. After excavating approx. 500 tonnes of earth and stone, a full lime render was applied. Preserving the natural undulations of the walls at the customer’s request.

Ellon House, before.

Ellon House, after.

RENDER REPAIR to an old farm house in south Devon, the cob down there is notoriously sandy and doesn't deal well with trapped moisture. The previous lime render had let go of the wall creating a large crack (which we should have photographed!). After chasing away anything loose we had a nice, neat patch to redo. This required minimal repairs to the substrate, so after dubbing out any depressions we went straight onto the cob with a cob specific mortar, followed by 2 coats of lime mortar, and finally a hand-thrown roughcast finish. This would then be limewashed or painted with a breathable mineral paint to match the existing wall.

Failed render removed - revealed cob & plinth

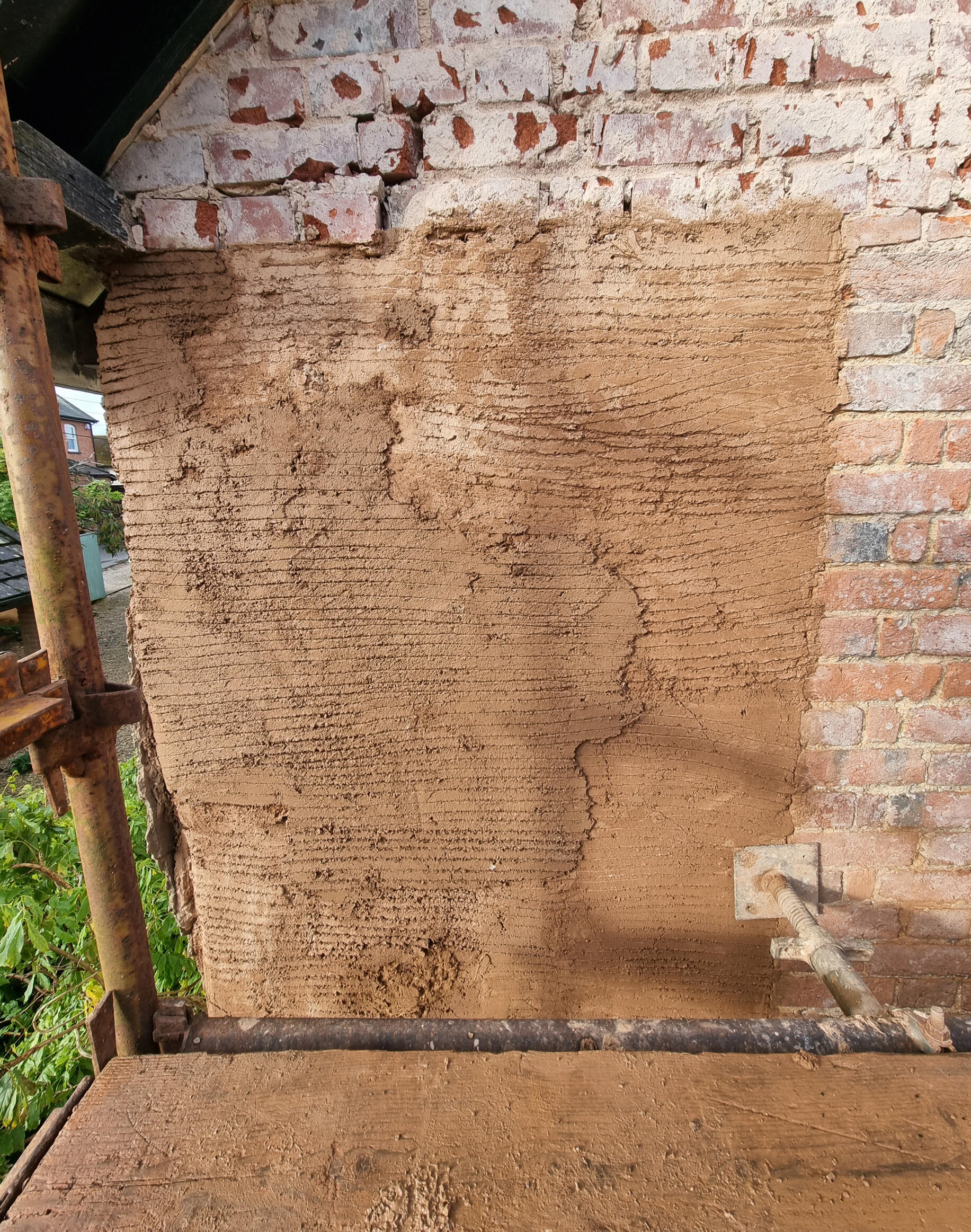

Cob mortar - scratch coat

Lime mortar - brushed floatcoat

Hand thrown topcoat - roughcast

COB REPAIRS & RENDER - The render on the end wall of an old Devon house failed after a few harsh winters. Upon removing the damaged render, we discovered a full brick chimney breast flanked by cob walls on either side. We identified several minor repairs needed (e.g. bricks had been incorrectly used to patch missing cob, or cement patches). Over time, lime render tends come unstuck from the cob. After decades of repairs, we have developed a specialized cob mortar that binds more effectively with the substrate, creating an intermediate layer that bridges the transition between cob and lime.

Failed brick repairs - left flank.

Cob block repair and dubbbing out.

Bringing up to level with multiple layers of mortar.

Cob mortar - right flank.

Failed brick repair - right flank.

Cob block repair, replacing brick.

Lime mortar, brushed - intermediate coat.

lime mortar - intermediate coat.